±320-525kV DC cable joint

Range to: ±525kv DC cable accessories Applied for: Extra high voltage project, such as new energy, sea power

CLASSIFICATION:

±320kv/ ±500kv DC cable joint

keyword:

Changlan Electric

Online Inquiry

*DC ±320kV and ±525kV Cable Joint

*Product Standard

GB/T 31489 DC Extruded Cable Systems for Power Transmission at a Rated Voltage up to 500kV

GIGRE 496-2012 Recommendations for Testing DC Extruded Cable Systems for Power Transmission at Rated Voltage up to 500kV

TICW 7.1-2012 Technical Specification of DC Extruded Cable Systems for Power Transmission at a Rated Voltage up to 500kV Part 1: Test methods and requirements

TICW 7.4-2012 Technical Specification of DC Extruded Cable Systems for Power Transmission at a Rated Voltage up to 500kV Part 4: DC cable accessories

Q/OKAB 033-2017 DC Extruded Cable Systems for Power Transmission at a Rated Voltage up to 500kV

*Product Type/Application Range

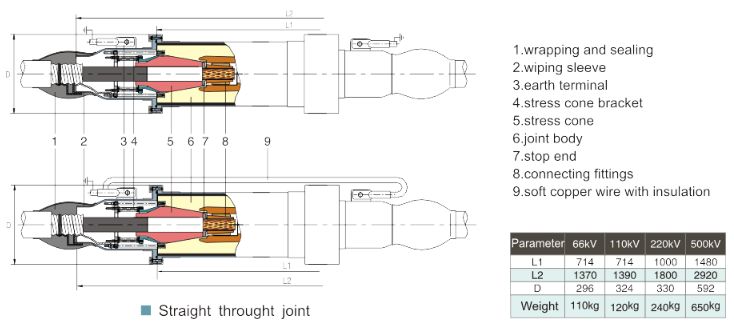

Straight joint: DC-JTZ2; Insulation joint: DC-JJZ2;

Rated voltage: ±320kV For cable cross section: 240-3000mm2

Rated voltage: ±525kV For cable cross section: 800-3000mm2

Note: DC accessories of other voltage levels can be customized according to requirements.

*Product Characteristics

Nano-filler was used to modify EPDM insulation material. This prescription is specially designed for DC cable accessories, which can keep the original advantages of good electrical and mechanical performance of EPDM, also reduce and even the space charge in material. This makes that conductivity of material in different temperature matches with cable insulation and solved the problem of space charge accumulation in insulation interface.

The cone bracket with spring presses stress cone clings to the inner cone wall of main body. Thus it overcomes the disadvantages of elastic relaxation due to material aging, bad contact between stress cone and cable outer semi-cond. layer etc, and ensured long term stable and safe operation of joint.

Joint main body is made from high-strength epoxy resin after vacuum molding, which is water-proof, damp-proof and resistant to mechanical damage.

Joint adopts whole-dry structure, with no leakage problem.

Joint can be installed in cable pit and cable trench, also can be buried directly. It uses small installation space.

Joint is easy to install (Only insert in well treated cable) with plug-in, compression free structure ferrule.

*Product Drawing

Insulation Joints

Download

If you have an interest, please contact us by message!